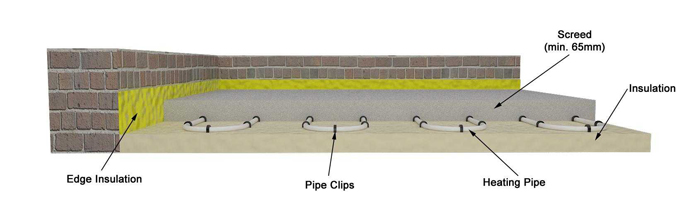

Solid Screed Floor

Wall/Edging insulation:

Fix the edge insulation continuously around all internal walls. When installed correctly the PE-skirt will be facing out. Tape the PE-shirt onto the floor insulation.

Once the screed has dried and cured, the edging insulation can be trimmed down.

Remember the following:

Maximum circuit length is 100m. If your area requires more than 100m divide it in half and fit two circuits of similar length. For example: Room area 30m2 with pipe centres 200mm require 150m of pipe. Fix with 2 circuits of 75m.

Pipe connections must not be made in the area to be screeded.

Don't forget to allow for connection lengths back to the manifold in overall circuit design and length.

Pipe centres:

Pipe should be spaced 100mm away from the wall. Always go with flow to the coldest part of the room first e.g. under windows, along outside walls.

In solid screed floors and areas of average to low heat loss UFH pipe is generally laid at standard centres of 200mm, unless otherwise specified.

There are the two most common ways to install the pipe into the floor insulation: pipe clips or using the rail system.

Pipe Clips Fixing:

Pipe is being fixed with clips provided. We recommend two people to fit the pipe, one person to hold the coil and another person to clip the pipe into the insulation. You need approximate 2 clips per metre of pipe.

Rail System Fixing:

With this type of installation lay the rail across the floor to create a matrix for pipe. Rails have the self adhesive backing so you can easily stick them to the insulation. Set them with a maximum of 500mm from two opposite wall edges and a maximum of 1000mm spacing between clip rails. Make sure that the rail is at 90° angle to the coldest external wall.

Once you are happy with the clip rail layout fix them permanently to the insulation using additional pipe clips. Also make sure that the pipe turns are secured with additional pipe clips.

Try to use all the pipework supplied. The pipe is marked every metre so you know when it's time to go back to the control unit.

Pipe isn't normally laid under fixed furniture such as kitchen and utility units.

Screed:

We recommend 65mm of screed on top of the insulation (Building Regulations requirements)

The screed must be allowed to dry before heating is operated. The general rule is to allow 1 day per 1 mm of screed.

As the system is used for the first time, the mixing valve must be set to the minimum setting to let the moisture in the screed to dry out. The temperature should be increased by 2 degrees every day until the mixing valve is set at 45°C.

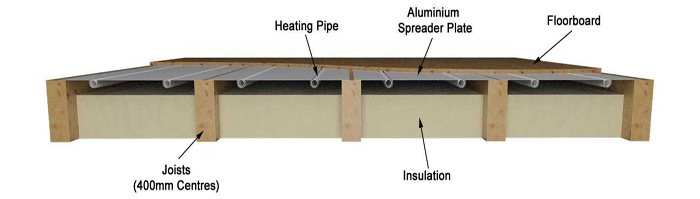

Timber Suspended Floor with Heat Emission Plates

Adept Aluminum Spreader Plates are 1000x390mm and they are suitable for Timber Suspended Floor with floor joists at 400mm centres.

It's essential that insulation is installed between the joists, as close as to the underside of the plates as possible. Usually a minimum of 100mm of mineral wool insulation is used, however, where relevant, the insulation used must comply with current Part L and Part E of the Building Regulations.

Plates normally cover approximately 80% of the floor area and are only laid under straight runs of pipe.

Ensure all insulation and battening work is installed and complete before laying the plates down.

Lay the plates down without fixing. Plates should never touch each other, as they expand when heated so ensure that you leave a gap between ends and sides of each plate. Check to ensure proper number of plates are evenly spread out across the heated area before fixing.

Leave a minimum 300mm gap from the wall to enable the pipe to bend 180° around.

When required area is covered with plates fix them down with a staple gun or tacks and lay down the pipe into the grooves in the plates.

With this system the flow temperature on the mixing valve should be set up for 55°C.

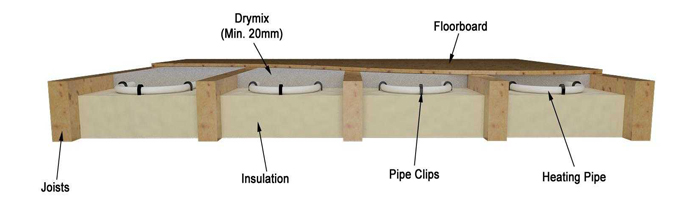

Timber Suspended Floor with Drymix Infill

Drymix - 8:1 damp sand/cement biscuit mix, 20-25mm thick.

The Drymix is needed for Ground Floor, older buildings and if concrete floor and timber suspended floor are on the same floor.

Always check if your floor can take an extra load of the Drymix (20kg/m2).

Drymix infill system:

Doesn't increase floor height but joist notches are required for pipe to pass from bay to bay.

Min 50mm of insulation (Kingspan or Celotex-refer to building regulations) must be installed between the joists.

When joists centres are 400mm, pipe is clipped into insulation at 200mm centres (unless other specified) with pipe clips.